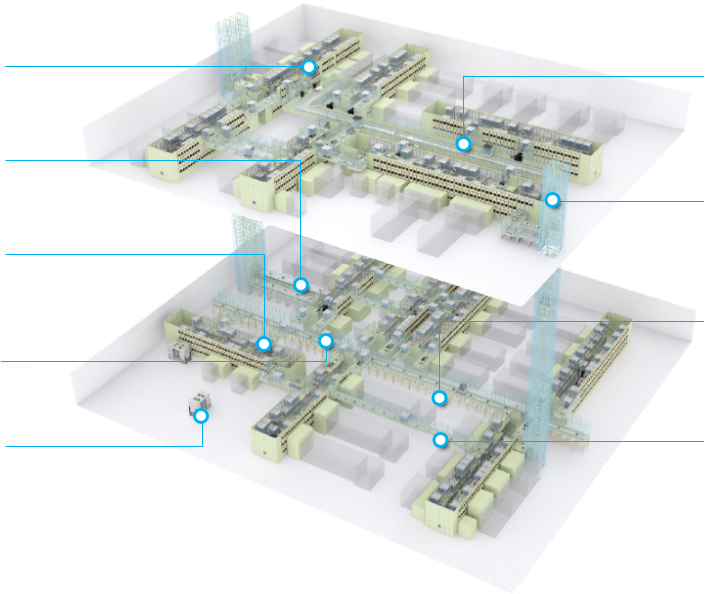

Display

Provides AMHS Solution optimized for LCD / OLED production process

Stocker

Use

Inter-process material transport system with cassette storage and transport function

Features

- Fast, Efficient Storage and Retrieval

- AGV/MGV/OHS Compatible I/O Port

- SECS/HSMS/GEM Compatible

- Contact-less Power Supply

Specification

- PayloadMax. 2,000kg

- SpeedMax. 210m/min

- Forking Time7 sec ~ 12 sec

- CleanlinessClass 10@0.1㎛(Anti-Particle Design)

OHCV (Curved)

Use

Material equipment that transports cassettes between stockers through the top for efficient space utilization

Features

- Application of Curved Rail

- educing Number of Carriage

- Short Cycle Time

- Easy to Configure Layout

Specification

- PayloadMax. 2,000kg

- SpeedMax. 180m/min

- Power SupplyContact-less Power Supply

- Cleanliness Cleanliness Class 10@0.1㎛(Anti-Particle Design)

OHT (Overhead Hoist Transport)

Use

Material equipment that transports goods directly to the process equipment in long distance zones and areas with large amounts of transport, installed under the ceiling for efficient space utilization

Features

- Direct Interface With Stocker To Process

- Equipment or Buffers

- Rail TypeSingle Rail

- Routing DeviceTurn Table/Rail Shifter

- Use For Cell To Module Transfer

Specification

- PayloadMax. 600kg

- Traveling VelocityMax. 180m/min

- Hoisting Speed Contact-less Power Supply

- Gripper Base

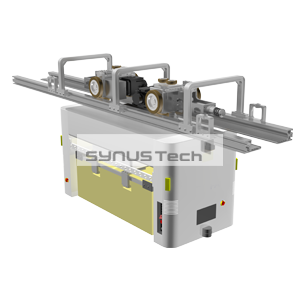

RGV (Rail Guided Vehicle)

Use

Unmanned transport equipment that transports cassettes between process equipment, stockers, and buffers along rails

Features

- Excellent Substitute for AGV System

- Direct Interface with Process Equip. or Buffers

Specification

- PayloadMax. 2,000kg

- SpeedMax. 210m/min

- HForking Time 7 sec ~ 12 sec

- Cleanliness Class 10@0.1㎛(Anti-Particle Design)

AGV (Automated Guided Vehicle)

Use

Unmanned conveyance equipment that conveys cassettes between process equipment, stockers, and buffers

Features

- Excellent & Flexible Delivery System

- Direct Interface with Process Equip. or Buffers

- Steering Wheel Drive

- Auto Charging System

- SCARA or Slide Fork

Specification

- Payload100 ~ 1,500kg

- SpeedMax. 60m/min

- Load Time15 sec ~ 32 sec

- CleanlinessFab -Class 10@0.1㎛(Anti-Particle Design)

Pkg -Class 1000@0.5㎛(Anti-Particle Design)

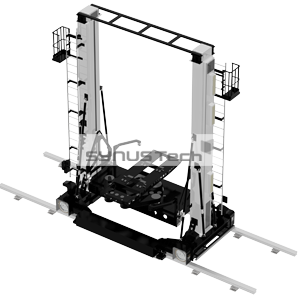

Clean Lift

Use

Equipment that vertically conveys cassettes at inter- or intra-layer level during the FPD process

Features

- AGV/RGV/OHCV/STK Compatible I/O Port

- High Efficiency

- Optimize Safety Interlock

Specification

- PayloadMax. 3,000kg

- SpeedMax. 120m/min

- StrokeMax. 97m

- CleanlinessClass 10@0.1㎛(Anti-Particle Design)

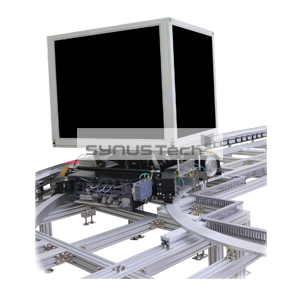

OHS (Over Head Shuttle)

Use

Equipment that transports cassettes in long distance zones and areas with large amounts of transport, installed under the ceiling for efficient space utilization

Features

- Minimum Curve Radius

- Compatible with High Cleanliness

- High Efficiency

- Compact and Slim Design

Specification

- PayloadMax. 2,000kg

- Traveling VelocityMax. 210m/min(curve 45m/min)

- CleanlinessClass 10 @0.1㎛(with Exhaust Filter)