Artificial intelligence

We research and develop products that integrate artificial intelligence technology with the material field for the first time in Korea.

We research and develop AI-based intelligent factory automation technology and operation platform

It solves inefficiencies (Congestion, load and idle equipment mismatching, load unbalance, standby, etc.) that humans cannot solve due to the complexity of material and implements automation that enables autonomous operation.

- On-site adaptive autonomous driving system (recognition of congestion, product change, production change and securing optimal alternative)

- Optimal routing and dispatching of material equipment

- System control and suggestion of abnormal signs

- Development of AI-based material equipment operation system

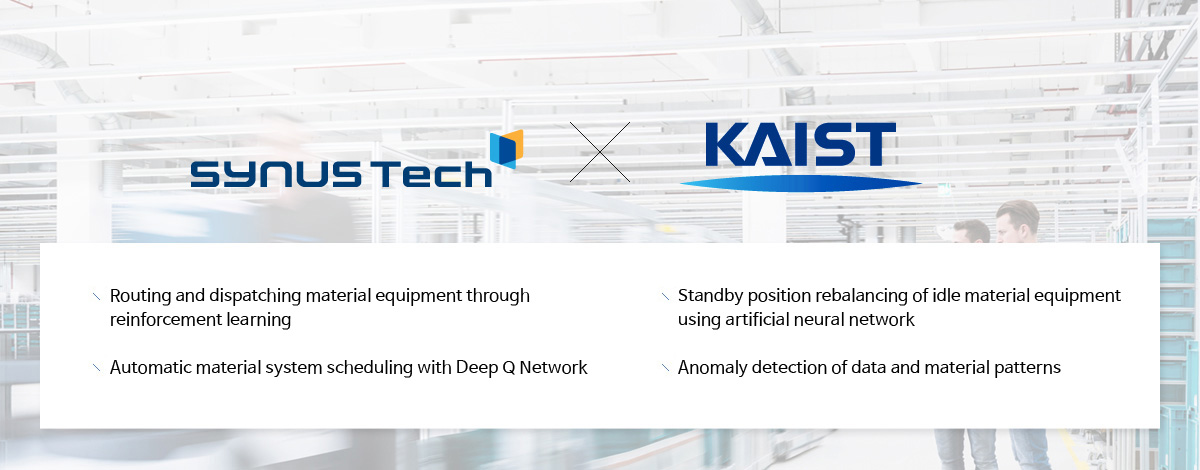

SYNUS Tech-KAIST AI AMHS Research Center

In 2015, we started with a research cooperation MOU on overall automated material systems, jointly conducted a number of industry-university projects and opened it for research and commercialization of industrial intelligence.

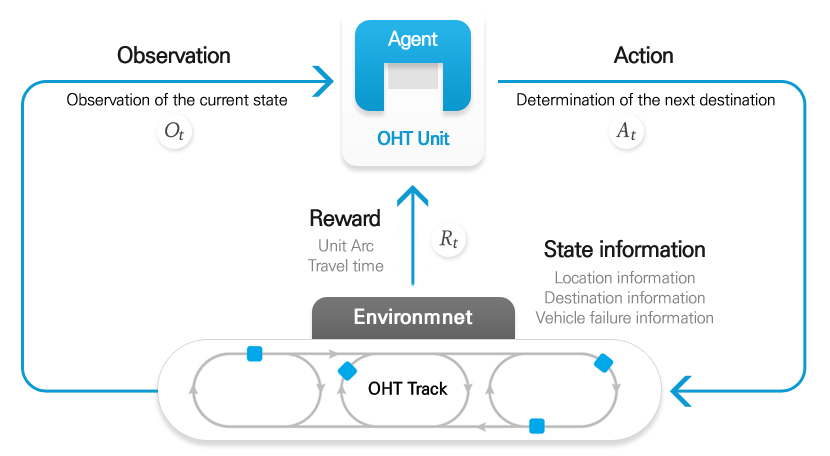

OHT (Overhead Hoist Transfer) System applied with reinforcement learning

It’s to match efficiently and operate large number of conveyance requests and multiple vehicles (Hundreds to 1,000 units) in large and complex layouts and to respond to preemptive congestion and process changes through analysis of conveyance history data

- Large scale vehicle operation (over 1,000 units)

- Recognizing process changes and responding to conveyance pattern changes

- Improving the efficiency of system operation by avoiding congestion

- Flexible response by increasing the number of vehicles when production volume increases

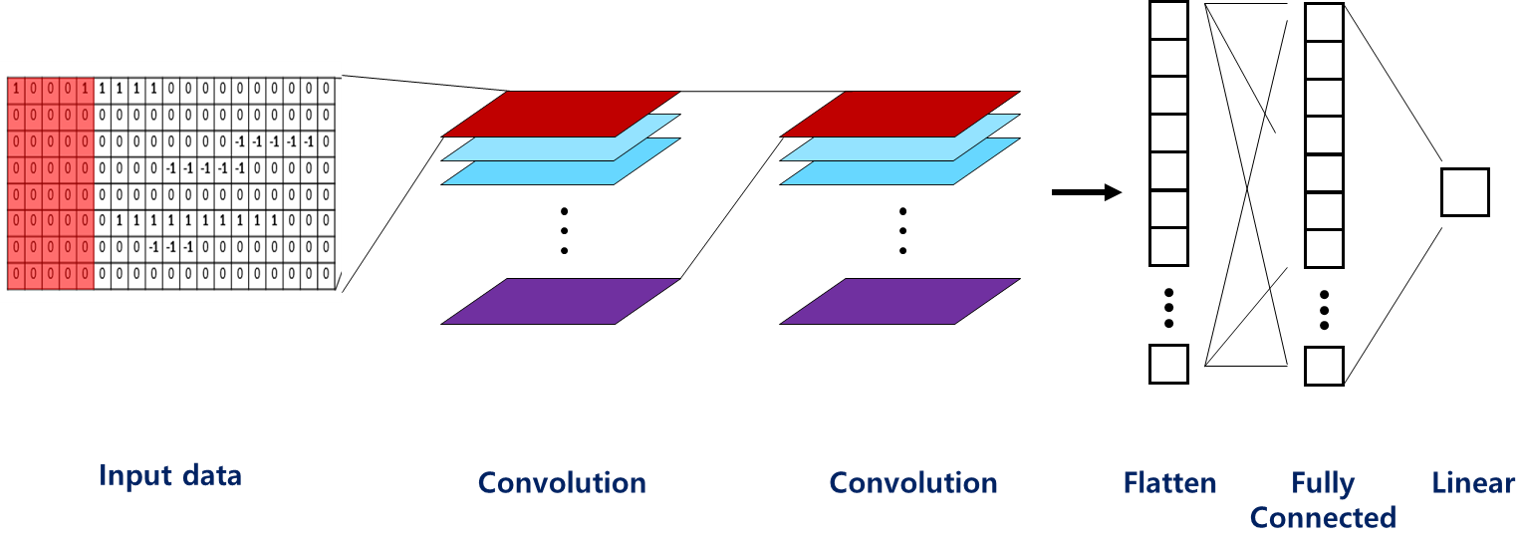

Stocker Operation with Deep Q Network

The movement trajectories of S-Masters and conveyance commands in the Stocker are represented in a matrix, and the learning using the Deep Q Network avoids collisions between S-Masters and operates efficiently without restriction in the moving area.

- Conveying without restriction of moving area while avoiding collision between S-Master

- Hand-off conveyance between S-Masters is eliminated to increase the handling capacity

- Reduced wait time after conveyance request

- Material moves smoothly within Fab by eliminating Bottleneck Stocker