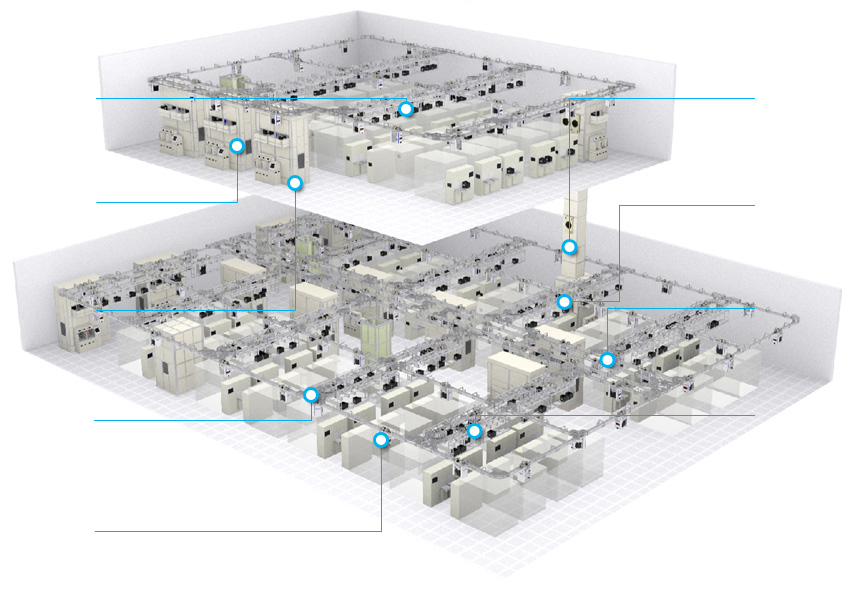

Semiconductor

Implements maximum efficiency production system of semiconductor production process

SEMI OHT (Overhead Hoist Transport)

Use

Material transport system between semiconductor processes installed under the rail

Features

- Minimum Turning Radius

- Dual Rail Track

- OHS & OHT Port Access

- Active Slide Architecture

- Compact & Slim Design

Specification

- TypeFOUP, FOSB, Megazine, Tray, Cassette

- Payload8~20Kg

- SpeedStraight 3.5m/sec, Curve 0.7m/sec

- Elevator Speed0.9m/sec

- Curve RadiusR500mm (45˚, 90 ˚)

- CleanlinessClass 10@0.3㎛(Anti-Particle Design)

Pkg- Class 1000@0.5㎛(Anti-Particle Design)

SEMI STOCKER

Use

Inter-process material transport system with FOUP storage and transport function

Features

- Superior Cycle Time

- Flexible Port Configuration

- Optimize Safety Interlock

- Contact-less Power Supply

Specification

- PayloadFOUP, FOSB, Cassette, Megazine, Tray

- Movement AxesX-axis, Z-axis, Turning, Forking

- Forking TimeForking Time: 2 sec

- CleanlinessFab -Class 10@0.3㎛(Anti-Particle Design)

Pkg- Class 1000@0.5㎛(Anti-Particle Design)

Bank STOCKER

Use

Wafer Test- Bank(Wafer sorting / Split, Merge)

- Storing & transport t in bank process during PKG&Test

Features

- Twin S-Master

- Storing over 1,000 cell

- Sorter Docking

Specification

- PayloadFOUP, FOSB

- Movement AxesX-axis, Z-axis, Turning, Forking

- Tact Time12 sec (Forking Time: 2 sec)

- CleanlinessClass 10@0.3㎛(Anti-Particle Design)

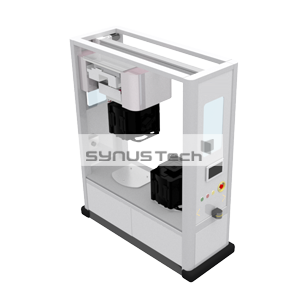

SEMI AGV (Automated Guided Vehicle)

Use

Equipment that automatically conveys conveyed goods such as FOUP, Cassette, etc. to Stocker and EQ equipment during semiconductor process

Features

- Excellent & Flexible Delivery System

- Direct Interface with Process Equip or Buffers

Specification

- PayloadMax. 20Kg

- Use to Handle TypeFOUP, FOSB, Cassette, Megazine, Tray, etc.

- Load/Unloading Time25~30sec

- Traveling VelocityMax. 56m/min

- CleanlinessClass 10@0.1㎛(Anti-Particle Design)

Pkg- Class 1000@0.5㎛(Anti-Particle Design)

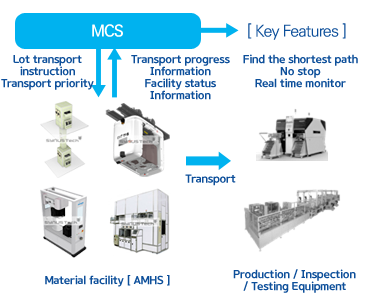

MCS (Material Control System)

Use

By finding the shortest path between material facilities received from MES, it’s to realize full automation through real-time monitoring of control transport of each material facility

Features

- Real-time monitor in-house transport equipment for AMHS equipment and materials

- Support SEMI standard (SECS, GEM, Stocker-SEM, IB-SEM)

- Efficient Dynamic Routing according to factory state

- Apply the Shortest Path

- Load Balancing

- J2EE Platform independent on OS

- Run-Time Patch

- Respond to Auto Failover Active-Active structure

- Support various DBMS and Middleware

Specification

- Correspondence equipmentOHT, Stocker, OHB, Lift, AGV

- based protocolIB-SEM / Stocker-SEM

- Auto FailoverActive-Active

- Business LogicBPEL-based

- ScalabilityEasy integration with various Host / AMHS

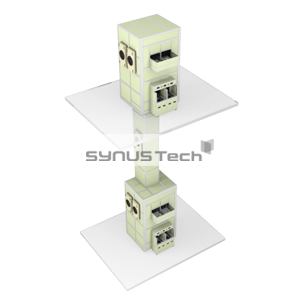

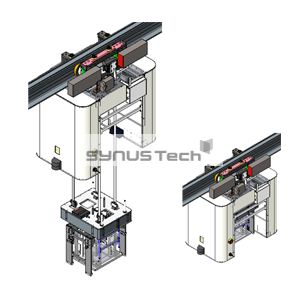

SEMI HT (High Speed Tower)

Use

Equipment that vertically conveys FOUP at inter- or intra-layer level during the semiconductor process

Features

- Double Transport(2 FOUP) System

- Short Cycle Time

- Fast Moving Speed

- Fast Cargo(FOUP, FOSB) System Between Multi Floor

Specification

- Payload300mm FOUP, FOSB

- Height25 ~ 60m

- Up/Down SpeedMax. 250m/min

- CleanlinessFab -Class 10@0.3㎛(Anti-Particle Design)

Pkg- Class 1000@0.5㎛(Anti-Particle Design)

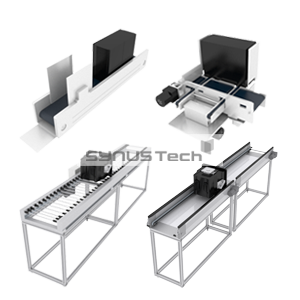

Conveyor

Use

Material system that transports FOUP, Cassette, etc. horizontally and can also load them as a buffer

Features

- Flexible with Module Unit

- Dual Belt for Minimum Tray Contact

- Miniaturization / weight lightening

Specification

- Driving MethodInduction Motor / Inverter Control

- SpeedMax. 30m/min

- Drive(Turn)Servo Motor

- Turn Speed 5sec / 90º, 8sec / 180º

- Traveling Speed 15sec @ Stroke 1435mm

LHT (Local Hoist Transfer)

Use

Unlike OHT, which conveys linear section of EQ section from EQ in the semiconductor processes, rail configuration is simple

Features

- Simple

- Speedy Tact Time

Specification

- PayloadFOUP, FOSB, M/Z, Tray, Cassette

- Travel Speed2m/sec

- Elevator Speed 0.48m/sec

- CleanlinessFab -Class 10@0.3㎛(Anti-Particle Design)

Pkg- Class 1000@0.5㎛(Anti-Particle Design)

SIS (Sorter In STOCKER)

Use

- FOUP / FOSB Wafer Split, Merge function is included

Features

- Minimized Lay-Out composition is available

(Square shape / Sorter 2 unit composition)

Specification

- PayloadFOUP, FOSB

- Movement AxesX-axis, Z-axis, Turning, Forking

- Tact TimeForking Time: 2 sec

- CleanlinessClass 10@0.3㎛(Anti-Particle Design)

FIO (FOUP In Out System)

Use

System for in / out the product (FOUP, FOSB) from OHT

Features

- Minimized Lay-Out composition is available

(800mm × 800mm) - Easy to move

Specification

- PayloadFOUP, FOSB

- Movement AxesX-axis, Turning

- Speed0.25m/sec

- CleanlinessClass 10@0.3㎛(Anti-Particle Design)