Core Technology

We provide competitive AMHS Total Solution developed only by domestic researchers.

Core Technology

- Various layout design by generation (G3 ~ 11)

- Customer's optimal design and concept proposal

- Design professionals

- Optimization of logistics scheduling

- Real time monitoring and analysis

- Easy control and flexible operational changes

- Design based on various analysis

(Air_Particle Flow/Structure/Fatigue/Vibration/Process Analysis) - Improvement of product quality/Proactive prevention of problem

- Optimal PLC program development by product

- Acquisition of worker safety and product stability

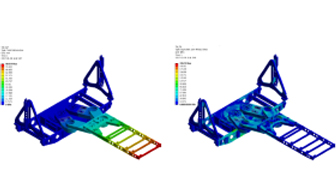

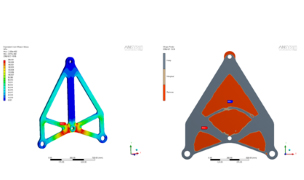

Structure Analysis

By doing predictive diagnosis through the simulation of the safety of deformation rate and stress that occur during operating equipment. we save time and cost in the stiffness review and ensure optimum design and reliability.

[ Stress & Deformation Analysis ]

[ Shape & Topology Optimization ]

[ Multi-Body Dynamic Analysis ]

- Evaluation of stiffness, stress distribution and deformation rate

- Prediction of structure response to external excitation

- Analysis of natural frequency and Mode Shad

- Derivation of optimal shape against strength

Product quality improvement and problem prevention

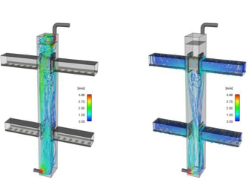

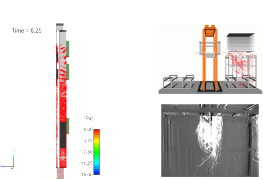

Air/Particle Flow Analysis

The optimal design related to cleanliness is carried out by applying simulation to the initial stage of product development of FAB and automatic material equipment and problems during operating.

[ Air Flow Analysis ]

[ Particle Behavior Analysis ]

[ HVAC System Optimization ]

- Prediction / analysis of airflow and particle behavior

- Analysis of the causes of airflow and particle problems and solution

- Preliminary review and improvement of system design

- Mutual understanding through visualization

Efficient cleanliness control through airflow optimization

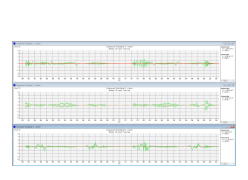

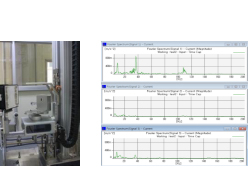

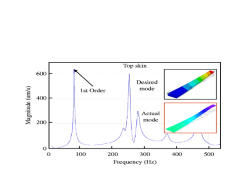

Noise / Vibration Analysis

By measuring / analyzing the noise and vibration signals generated during operation of the equipment, we secure stability and reliability through proactive diagnostics and equipment state.

[ Time Domain Analysis ]

[ Frequency Domain Analysis ]

[ Resonance Analysis ]

- Identification of equipment state through vibration analysis

- Analysis of the cause of vibration

- Acquisition / accumulation of various technical data

- Acquisition of vibration reduction technology

Improvement of equipment reliability with fault prevention

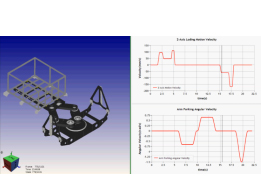

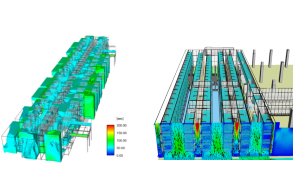

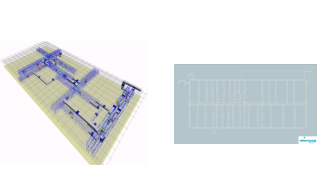

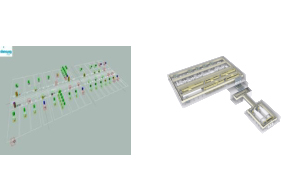

AMHS(Automated Material Handling System) Analysis

By analyzing the logistics flow according to the production process, we propose the optimal automated logistics system by calculating the performance and the required number of units such as cycle time and operation rate according to the transport volume and transport pattern of the material equipment through simulation.

[ Material Flow & Moves Analysis ]

[ AMHS Simulation Analysis ]

[ Production & 3D Visualization ]

- Review of production system and layout feasibility

- Analysis of production site problem and derivation of alternatives

- Selection of AMHS performance and quantity required

- 3D visualization of the production line

Establishment of optimal automated material system